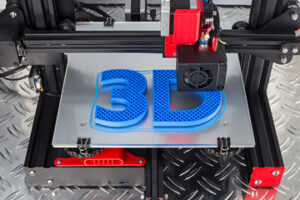

3D printing is a process in which a digital model is turned into a solid three-dimensional physical object. Unlike traditional manufacturing techniques that cut away materials, 3D printing creates objects by adding layers of material.

From fun figurines to product prototypes, to tactile maps and historical artifacts to sustainable habitats for deep space exploration, the possibilities are endless. Contact By3Design for professional help.

3D printing is a process for making physical objects from various materials based on a three-dimensional digital design. Unlike traditional manufacturing methods such as cutting away material from stock items, casting and forming parts in metal molds, 3D printers build up solid objects by adding layers of material on top of each other to create complex geometries and structures.

The resulting physical objects can be used to support a wide range of projects and activities, from fun figurines and jewelry to prototypes for engineers and architects. Students, teachers and researchers can also utilize the technology to analyze historic artifacts or investigate anatomical and molecular structures.

While many people think of 3D printing as a relatively new technology, the first commercially available 3D printers were introduced in the 1980s. Today, 3D printing is widely used in a variety of industrial and consumer applications.

To produce a 3D print, the user begins with a digital model, typically created using computer-aided design (CAD) software programs. The model is then converted into a series of coordinates that describe the geometry of the object and then saved as a file known as an STL (Standard Triangle Language) file. This is a universal file type that can be read by all 3D printers.

Once the STL file is loaded into a 3D printer, the printer “prints” a layer of material on top of each other until the object is complete. The most popular and affordable 3D printing technology is called fused deposition modeling or Fused Filament Fabrication, which uses a heated nozzle to extrude thermoplastic filaments like PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene) or PETG (Polyethylene Terephthalate Glycol) onto a platform to create the desired object.

More advanced technologies use liquid resins, powdered materials or metals to produce objects. Fused laser sintering (SLS) and Direct Metal Laser Sintering (DMLS) use UV lasers to cure a liquid or powdered material into a solid layer by layer, producing fine details and intricate components.

Materials

The materials that 3D printers use to create objects are incredibly important because they impact the final printed object’s strength, durability, flexibility and heat resistance. The right material also influences the aesthetics of the print.

The most popular 3D printing material is plastic filament, which comes in a variety of colors and has excellent layer adhesion to make it a very durable material. PLA is also the most environmentally friendly option and can be used to create everything from medical models to artistic pieces. It also works well with paint and super glue for customization after the print is finished.

Resins are liquid polymers that harden under UV light in stereolithography (SLA) and digital light processing (DLP) machines, and are a great choice for applications that require high precision and a smooth surface finish. Standard resins offer a balance of strength and cost effectiveness, while engineering resins have specific mechanical properties that make them ideal for functional prototypes and end-use parts in product development and engineering. Tough resin is engineered to mimic the stiffness and strength of ABS plastic while remaining flexible, and high-temperature resin withstands extreme temperatures for use in heat-resistant fixtures.

Other commonly used plastics in 3D printing include polypropylene (PP) and elastomeric thermoplastics such as polyurethane. PP is a partially crystalline plastic that offers a good combination of strength and flexibility with low moisture absorption, while elastomeric thermoplastics like polyurethane have good resilience and can flex up to 580% of its elongation before breaking.

In addition to conventional plastics, some printers are also capable of creating metal parts using a process called direct metal laser sintering (DMLS). In this technology, the machine’s bed is filled with powdered metals like aluminum and stainless steel, which are heated with laser beams for a quick, inexpensive production of high-quality metal parts.

The Library is currently offering PLA to YorCreate patrons, but we welcome the use of your own PLA for projects you have designed at home or for which you have a source file. The Library cannot help you design a model, but we can assist you with finding resources online or in-person to get you started.

Printing Process

The 3D printing process is often referred to as additive manufacturing (as opposed to conventional machining, casting and forming which involve subtracting material). It works by building up an object layer by layer from a digital model, much like traditional printers print words or images onto paper. Each printed layer adds to the total height of the finished product.

3D printing can be used to produce a wide variety of parts and products. The processes and materials vary by printer, but they all share one thing in common: they start with a digital 3D design file. This file is then ‘sliced’ into thin layers, each of which the printer prints onto a bed of starting material. The thickness of each slice determines how long it takes to complete the print and the overall part dimensions.

Each sliced layer is then solidified with a binding agent, typically a liquid. Some processes, such as Fused Deposition Modelling (FDM) and Directed Energy Deposition (3D PEEL), use heat to melt the starting material into a solid. Others, such as SLS, DMLS and EBM, use a laser beam to consolidate powdered material into the desired structure.

Other 3D printing technologies, such as photopolymer jetting and binder jetting, use a moving print head with nozzles connected to containers of liquid photopolymer resins. The nozzles spread the resin in areas that correspond to the geometry of a given layer onto a build platform, which is then cured with UV light. The printed part is then rinsed off and trimmed of support structures if required. For some materials, the final printed part may require post-processing such as further sintering or heat treatment.

All of these processes can produce highly detailed, full-colour, and multi-material printed parts, but they can take time. Compared to conventional manufacturing, this is why Geomiq 3D printing is so attractive – it can make complex, high-value, single parts and assemblies significantly faster.

Applications

3D printing is a process that creates real, physical objects from a digital model using a variety of plastics and resins. It is often called additive manufacturing because it builds an object layer by layer rather than removing material from a stock item like traditional machining, casting and forging processes do. 3D printing allows manufacturers to quickly make prototypes and test out different sizes, shapes and assembly options that may otherwise be difficult or impossible. This shortens the development time, helps reduce costs and allows for iterative changes before production starts, resulting in better, more cost-effective products.

While the 3D printing process varies by technology, most use a computer program that converts a three-dimensional digital model into a series of two-dimensional slices. Each slice represents a specific part of the final product. The software then tells the printer to solidify a specified amount of starting material on each layer of the printed object. Once all of the slices are printed, they can be assembled to form the final product.

In addition to standard plastics and resins, 3D printing can be used with a wide range of other materials including paper, ceramics and bio tissues. 3D printing also has the potential to be used in healthcare, enabling the creation of patient-matched medical devices, including implants and prosthetics.

Medical applications of 3D printing are growing rapidly. For example, surgeons can prepare and practice surgical plans with 3D models of damaged organs or anatomical specimens before the actual operation. This can allow them to study the defect and try out various approaches, resulting in shorter operations, reduced risk of complications and improved outcomes for patients.

Other medical applications include the creation of prosthetics and dental appliances that can be made in just a few hours. Patients can also be fitted with custom-made devices based on individual anatomic features that are captured by medical imaging.

3D printing can even be used to create replacement parts for existing medical equipment such as ventilators and heart valves. The ability to print replacement parts at lower cost, in just a few hours, could significantly improve the availability of these vital pieces of medical equipment and help cut down on waiting lists for patients who need them.